اترك رسالة

Economic and SocioEnvironmental Benefits of Dry

These findings are vital to the magnetite industry, particularly in water and energyscarce regions as a benchmark for future studies aimed at deepening and expanding the knowledge base of dry

Mineral and Technological Features of

Based on the obtained results by the investigation of the features of magnetite–hematite ores from the Mikhailovskoye deposit, a

Mineralogical and Textural Characterisation of Iron Ore from a

China, and major iron ore price increases Magnetitehaematite skarn deposits are already considered a significant contributor to Chinese iron ore reserves (Zhai et al, 1996) In

Magnetic separation studies for a low grade siliceous iron ore

The major impurity present in the ore is silica containing Dry magnetic separation studies Beneficiation studies were under taken by using magnetic

Beneficiation of Magnetite Ores

Typical magnetite beneficiation is carried out as a wet process, and it consists of comminution, wet magnetic separation (to concentrate the magnetite mineral), reverse

Beneficiation of Magnetically Separated IronContaining Ore

Rough processing of iron ore employs dry methods which means that equipment is tuned to process large particles, but fine magnetic material less than a few

Intensifying the dry magnetic beneficiation of iron ores

L A Lomovtsev, R S Ulubabov, and A S Vikul, “Improvement and expansion of the use of dry magnetic concentration for iron ores — a promising approach to making mining

A Novel Pneumatic Planar Magnetic Separator for Magnetite Beneficiation

In our previous studies, we investigated the performance of a novel pneumatic planar magnetic separator (PMS) for the dry beneficiation of a selected magnetite ore In the present study, we have extended the studies on the PMS with the focus on investigating how various PMS processing flowsheet configurations influence its

Ore Beneficiation an overview ScienceDirect Topics

The principal separation in iron ore beneficiation, therefore, is between the iron minerals, hematite and/or magnetite, and silica, principally in the form of quartz The use of flotation, either alone or in combination with magnetic separation, has been well established as an efficient method for rejecting silica from these iron ores

Beneficiation of Iron Ores IspatGuru

Fig 3 Types of processing ores The wet processing (Fig 4) is normally practiced for low / medium grade (60 % Fe to 63 % Fe) hematite iron ore The wet process consists of multistage crushing followed by

POTENTIAL APPLICATIONS FOR DRY BENEFICIATION OF IRON ORE

manufacturing [12] Iron ores have a wide range in chemical composition especially for Fe content and associated gangue minerals [1] Major ironbearing minerals are hematite, goethite, limonite and magnetite [1,3] and the main contaminants in iron ores are 𝑆𝑖𝑂2 and Al2O3 Each mineral deposit has its own unique

Mineralogical and Beneficiation Studies of a Low Grade Iron Ore

Investigations were carried out, to establish its amenability for physical beneficiation on a low grade siliceous iron ore sample by magnetic separation Mineralogical studies, with the help of microscope as well as XRD, SEM–EDS revealed that the sample consists of magnetite, hematite and goethite as major opaque oxide

Beneficiation of Magnetite Ores

minerals Article Economic and SocioEnvironmental Benefits of Dry Beneficiation of Magnetite Ores Emmanuel Baawuah 1,*, Christopher Kelsey 2, Jonas AddaiMensah 1,3 and William Skinner 1 1 Future Industries Institute, University of South Australia, Mawson Lakes, SA 5000, Australia; (JAM);

Beneficiation of Magnetically Separated IronContaining Ore

Rough processing of iron ore employs dry methods which means that equipment is tuned to process large particles, but fine magnetic material less than a few tenths of a millimeter in size is not separated as efficiently The relevance of this study is determined by the fact that dry beneficiation waste contains recoverable ironbearing

(PDF) Economic and SocioEnvironmental Benefits of Dry Beneficiation

The present study investigates the economic and socioenvironmental benefits of applying these technologies in conceptual dry magnetite ore processing flowsheet The outcome of the study is

Beneficiation of Iron Ore 911 Metallurgist

Beneficiation of Iron Ore and the treatment of magnetic iron taconites, stage grinding and wet magnetic separation is standard practiceThis also applies to iron ores of the nonmagnetic type which after a reducing roast are amenable to magnetic separation All such plants are large tonnage operations treating up to 50,000 tons per

Beneficiation of LowGrade Dilband Iron Ore by Reduction

This research is aimed at the upgradation of indigenous Pakistani iron ore, ie, Dilband iron ore (hematite), by utilizing common metallurgical processes First, the magnetic properties of the ore were determined Initially, the iron ore samples contained 34 wt % Fe in addition to other gangue materials Therefore, the ore was subjected to a

Iron Ore Beneficiation ST Equipment & Technology

Iron ore is the fourth most common element in earth’s crust Iron is essential to steel manufacturing and therefore an essential material for global economic development Iron is also widely used in construction

Iron ore beneficiation: an overview ScienceDirect

Iron ore processing operating practices vary depending upon the the quality of iron ore deposit For highgrade ore, dry or wet processing can carried out and for lowgrade ore beneficiation is needed to make it suitable for iron making Typical flowcharts for processing different types of deposits and their usage is given in Fig 28

Characterization and Beneficiation of Dry Iron Ore Springer

Current industrial practice of processing of iron ore fines in India does not involve much beneficiation However, few plants in India are treating fines during washing, classification, and jigging process [4] In other parts of the world, iron ore fines are beneficiated for magnetite and hematiterich iron ore in * P Dixit prashantdixit

Economic and SocioEnvironmental Benefits of Dry Beneficiation

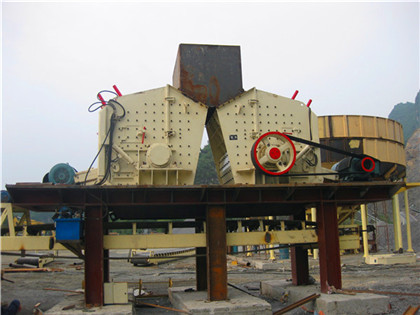

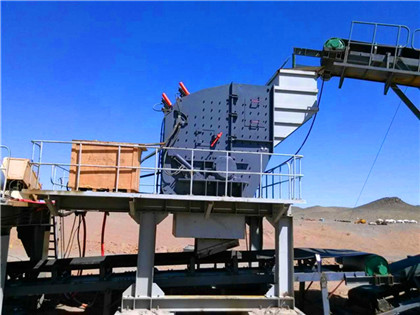

In our previous studies, we demonstrated the performance of novel superfine crusher and pneumatic planar magnetic separator as energyefficient technologies for dry processing of magnetite ores The present study investigates the economic and socioenvironmental benefits of applying these technologies in conceptual dry magnetite ore processing

Physical separation of iron ore: magnetic separation

December 2015 This chapter introduces the principle of how lowgrade iron ores are upgraded to highquality iron ore concentrates by magnetic separation Magnetite is the most magnetic of all the

Physical separation of iron ore: magnetic separation ScienceDirect

Lowgrade iron ore mined from the earth is usually composed of several minerals, desirable and undesirable Magnetic separation means applying a magnetic field of appropriate intensity, gradient, and other conditions to separate different minerals according to their differences in magnetic susceptibility 93

Processing of Magnetite Iron Ores–Comparing Grinding Options

The iron ore beneficiation plants normally include a series stages of size reduction (in order to achieve the desired liberation degree), increasing iron ore grade (magnetic separation), and

dry iron ore beneficiation of magnetite in peru

developments in the wet and dry processing of lower grade The results of early laboratory test work on the development of an efficient and environmentally sustainable dry processing option for the beneficiation of lower grade magnetite ores were tabled by IMP Technologies Pty Ltd (IMPTEC) and Cyclomag PtyLtd at Iron Ore 2017 in Perth WA

Existing and New Processes for Beneficiation of Indian Iron ores

The iron ore industries of India are expected to bring new technologies to cater to the need of the tremendous increase in demand for quality ores for steel making With the highgrade ores depleting very fast, the focus is on the beneficiation of lowgrade resources However, most of these ores do not respond well to the conventional

Economic and SocioEnvironmental Benefits of Dry Beneficiation

In our previous studies, we demonstrated the performance of novel superfine crusher and pneumatic planar magnetic separator as energyefficient technologies for dry processing of magnetite ores The present study investigates the economic and socioenvironmental benefits of applying these technologies in conceptual dry