اترك رسالة

Dry beneficiation technology of coal with an air dense

1 Introduction Dry beneficiation of coal with an air densemedium fluidized bed is an efficient coal separation method, which uses a gassolids fluidized bed as the separating medium, contrasting with the conventional methods of coal preparation

v115n8a13 Influence of medium particle size on the separation

density clean coal in highdensity reject coal increases as the medium particle size decreases More importantly, when the fluidizing bed consisted of −300+212 µm size

Development of Air Dense Medium Fluidized Bed Technology For

Abstract Wet processing of coal requires a large quantity of water Waste generated from wet process ties up a significant amount of water and land The slurry ponds also pose

Liberation characteristics of coal middlings comminuted

Compared with no material floating at the density of 13 kg/L for middlings and the product ground by the ball mill, yield of this density for the product by the jaw

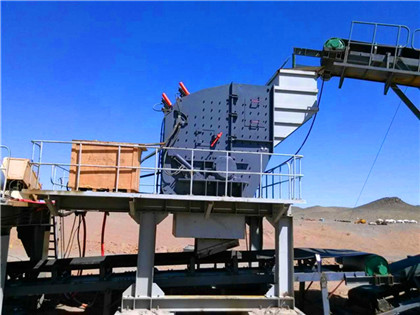

Performance Parameters of Jaw Crushers Download Table

A Study on the Effects of Coal Feed Size and Coal Type on the Performance of a Laboratory Jaw Crusher In this study, the effects at the three different coal size

Jaw Crusher an overview ScienceDirect Topics

The capacity of jaw crushers is a measure of the mass or volume of crushed material produced in unit time of operation From: Mineral Processing Design and Operations

Conventional and recent advances in gravity separation

Gravity separation, a technique that separates particles based on their differences in density, is widely used in coal cleaning due to the simplicity of its

DEVELOPMENT OF COAL DRY BENEFICIATION WITH AIRDENSE

The dry coal beneficiation technology with airdense medium fluidized bed utilizes airsolid suspension as beneficiating medium whose density is consistent for

PAPER OPEN ACCESS Development of dry coal gravity

One of the methods used in coal beneficiation process is dry method This method was popular at the beginning of the 20th century Then it was successfully used in the United

Liberation characteristics of coal middlings comminuted by jaw

This paper studied the liberation characteristics of middlings crushed with different kinds of fragmentation forces Middlings of −3 mm + 05 mm sampled from a

MECHANISM AND APPLICATION OF COAL DRY BENEFICIATION WITH AIR

MECHANISM AND APPLICATION OF COAL DRY BENEFICIATION WITH AIRDENSE MEDIUM FLUIDIZED BED* p¢ is density of gas(kg/m3) ; p~ is density of dense medium particles (kg/m 3) ; e is bed voidage pb is fluidized bed density, ie pb=pf¢+p~(1e) (3) medium particles is small ,which results in higher misplacing effect of viscosity

v115n8a13 Influence of medium particle size on the separation

Dry beneficiation of coal by air dense medium fluidized bed is an emerging Odisha, India The particle size was reduced by a Blake jaw crusher, followed by roll crushing and ball milling After size reduction, density clean coal in highdensity reject coal increases as the medium particle size decreases More importantly,

Evaluation of the separation performance of an air dense medium

A laboratoryscale ADMFB experimental system was designed and established to conduct the separation experiments of −13 + 6 mm coal As illustrated in Fig 3, the system was mainly consisted of an air supply system, an air controlling and adjusting system, a fluidized bed separation system, a parameter measurement and collection

Mixing and segregation behavior in an air dense medium

The particle density of solid material is one of the most significant factors affecting the adjustment of bed density for efficient dry coal beneficiation in an ADMFB with binary mixtures Ideally, a large density difference of the two types of solid particles is required for a wide range control of fluidized bed density [[14], [15], [16]]

(PDF) Dry beneficiation of +05mm56mm South African coal using an air

56mm+05mm coal particles), in an air dens e medium fluidized bed, were evaluated du ring this study To obtain the best operating conditions, the experiments were conducted under

Dry beneficiation of fine coal using planar air jets ScienceDirect

1 Introduction Coal plays a vital role in global energy mix In 2015, coal's share of global primary energy consumption is 292% [1]Coal beneficiation can improve coal quality by removing the gangue minerals and is the most effective and economic method for clean processing of coal resources [2], [3], [4], [5]In the last several decades,

Separation performance of coal in an air dense medium fluidized

Luo et al [33] sorted 50–6 mm coal at a separating density of 144 g/cm 3 using magnetic pearls as a medium to form an ADMFB with low density Duan et al [34] used fluidized bed system with air dense medium for pyrite recovery from 50 to 13 mm and 13–6 mm fractions and achieved recovery rates equal to 8169 and 7951, respectively

Dry coal beneficiation by the semiindustrial Air Dense Medium

Air Dense Medium Fluidized Bed system The schematic diagram of dry coal beneficiation in the Air Dense Medium Fluidized Bed is shown in Fig 1 Feed coal is introduced from the top of the fluidized bed separator In the ADMFB, feed coal is separated according to their densities with respect to the density of the gassolid fluidized bed

Ash limitation of physical coal beneficiation for medium–high

The intercept of 2–5% on the ash axis indicates an original inorganic component in coalforming peat The research result also presents a theoretical limitation of coal ash by coal cleaning, because 2–5% of inorganic components in medium–high quality ash coal could hardly be separated by traditional physical coal beneficiation

Modeldatabased switching adaptive control for dense medium

Accordingly, the optimization and stability of the dense medium density are critical for clean coal production, which has inspired the development of related control technologies Early researches on DMS control systems focused on the stable control of the dense medium density (Zhang et al, 2015, Zhang et al, 2016)

Minerals Ores Beneficiation and Refractories PDF Mill Scribd

collector to make sphalerite surface more hydrophobic • Depressants: Used in selective floatation by making certain minerals hydrophilic and preventing their floatation • pH modifiers: Floatation is preferred in alkaline medium because the collectors are stable in alkaline medium Corrosion is also reduced

(PDF) SIZE REDUCTION BY CRUSHING METHODS

A simplified model (kinematic diagram) of the mechanism of the double buckling jaw crusher is shown in Fig 20 The mechanism in question is a six membered mechanism formed by attaching a binary

Mineral Beneficiation and Processing of Coal SpringerLink

The modernday coal processing plants can be categorized into four different circuits, depending upon the size of the coal particles to be treated: (a) coarse coal processing circuit treating particles coarser than 10 mm, (b) small coal circuit for washing particles in the size range of 110 mm, (c) fine coal circuit for cleaning particles in size

Influence of Coal Feed Size on the Performance of Air Dense Medium

Beneficiation of small South African coal using an air dense medium fluidized bed Separation performance of coal in an air dense medium fluidized bed at varying feeding positions Fuel 2019, 243,449457 Influence of coal particle size and density Chemical Engineering Journal 2015, 260,240257

Fine coal dry beneficiation using autogenous medium in a vibrated

Dry beneficiation of fine coal (− 6 mm) using autogenous medium in a vibrated fluidized bed has been studied The results show that in the particulate bed of fine coal, most of − 1 + 05 mm size fractions of coal and a small portion of − 05 mm size fraction of coal having high ash content contribute to the formation of an autogenous

Coal beneficiation technology to reduce hazardous heavy metals

The main propose of the coal beneficiation is upgrading the quality of the run of mined coal by removing ash and sulfide minerals to reduce the ash and sulfur content of the coal to meet the specification that is set up by the customers (Noble and Luttrell, 2015, Miller, 2017)During the process, heavy metals associated with the ash and sulfide

FINE COAL AND THREE PRODUCT DRY BENEFICIATION WITH

Key words dry beneficiation; vibration fluidized bed; threeproduct separator The dry beneficiation technology with air dense medium fluidized bed can efficiently benefici ate the coarse coal of size 50~6mm However, this technology can not beneficiate efficiently the small coal of size ~6 mm for two reasons

Modeldatabased switching adaptive control for dense medium

52 Simulations based on the proposed control approach To verify the effectiveness of the proposed control method, the modeldatabased switching control approach and adaptive linear PI control algorithm were compared in two classic working situations: (1) changes in the set point of the ash content y s p (k); (2) frequent

Fluidization characteristics and fine coal dry beneficiation using a

The fact is that the bed density keeps fluctuating in a small range under the optimum operating parameters Study of the mechanism of fine coal beneficiation in air table Fuel, 154 (2015), pp 207216 Utilizing an air dense medium fluidized bed dry separating system for preparing a lowash coal

Valorization of South African Coal Wastes through Dense Medium

Over 70% of South Africa’s primary energy needs are still provided from coal To achieve market requirements, most of the runofmine (ROM) coal in South Africa (characterized in Table 1) is washedAs a result of beneficiation, approximately 30% to 40% of the total mass of coal mined in South Africa is, or has been, disposed as coal