اترك رسالة

china/ primary secondary crushers used in conveyor

Contribute to crushers/china development by creating an account on

11192 Crushed Stone Processing and Pulverized Mineral Processing

primary crusher Jaw, impactor, or gyratory crushers are usually used for initial reduction The crusher product, normally 75 to 30 centimeters (3 to 12 inches) in diameter, and

Primary Crusher an overview ScienceDirect Topics

Primary coal crusher: Used for larger coal size The primary coal crushers may be of different types such as: (1) coal jaw, (2) coal hammer, and (3) ring granulator

What is a Primary Crusher? Crushers, Excavators, Conveyors

A primary crusher breaks up large pieces of rock or concrete from the blasting or excavation process and turns them into smaller, more manageable chunks This is the

Primary Crusher: Handbook of Conveying and Handling of Scribd

Primary coal crusher: Used for larger coal size The primary coal crushers may be of different types such as: (1) coal jaw, (2) coal hammer, and (3) ring granulator

primary amp secondary crushers used in conveyor belt

英语网站资料 Contribute to boy/en development by creating an account on

An Effective Belt Conveyor for Underground Ore IOPscience

Basing upon a longtime experience in the field of analysing, testing, designing and computing of belt conveyor equipment with regard to specific operational

Crusher an overview ScienceDirect Topics

Jaw crushers are mainly used as primary crushers to produce material that can be transported by belt conveyors to the next crushing stages The crushing process takes

Primary Crusher: Handbook of Conveying and Handling of

Primary coal crusher: Used for larger coal size The primary coal crushers may be of different types such as: (1) coal jaw, (2) coal hammer, and (3) ring granulator Secondary coal crusher: Used when the coal coming from the supplier is large enough to be handled by a single crusher

What is a Primary Crusher? Crushers, Excavators, Conveyors

A primary crusher breaks up large pieces of rock or concrete from the blasting or excavation process and turns them into smaller, more manageable chunks This is the first step in the crushing process The smaller pieces can then either be prescreened or fed directly into a secondary impact or cone crusher

11192 Crushed Stone Processing

processed in the secondary crusher Cone crushers are commonly used for secondary crushing (although impact crushers are sometimes used), which typically reduces material to about 25 to 10 centimeters (1 to 4 inches) The material (throughs) from the second level of the screen bypasses the secondary crusher because it is sufficiently small for

Conveyor belt secondary cleaners TON

We recommend that a combination of primary and secondary belt cleaners be used TON supplies different sizes of conveyor systems depending on the volume of material to be conveyed Belt speed, belt size and pulley diameter all vary We do not classify our solutions according to industry segments, but rather according to the application within

How to Splice Crusher Belt Conveyor LinkedIn

How to Splice Crusher Belt Conveyor ? Report this post ZENITH Mineral Crusher what is a primary and secondary crusher? Feb 10, 2023

Selecting the right type of crushing equipment Quarry

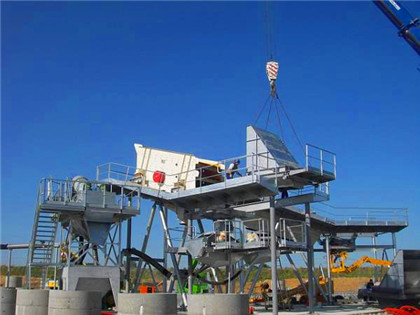

Primary crushing The duty of the primary crusher is, above all, to make it possible to transport material on a conveyor belt In most aggregate crushing plants, primary crushing is carried out in a jaw crusher, although a

OPERATION AND MAINTENANCE OF CRUSHER HOUSE FOR

Mostly E and F Grade Coal used in India classified by the degree to which they fragment the starting material, with primary and secondary crushers handling course materials, and tertiary and quaternary crushers reducing ore particles to finer gradations Each crusher is designed to work with a certain maximum size of raw material, and often

200 tph crusher plant LinkedIn

Typically, a 200 tph crusher plant consists of a primary crusher, such as a jaw crusher or a gyratory crusher, a secondary crusher, such as a cone crusher, a vibrating screen, belt conveyors, and

What Is Primary, Secondary, and Tertiary Crushing? Eagle Crusher

Secondary crushing, as you can imagine, is the second stage of material processing following its initial reduction At this stage, material will flow through perhaps a second impactor or even a cone crusher, which is effective at breaking down these types of material There are also tertiary and even quaternary stages of crushing that exist to

primary crusher belt

primary crusher belt Sampling Conveyor Belt for Crusher Circuit Survey Let’s review the steps to collect a sample of coarse rocks such as primary Crusher productThe procedure

Crusher

A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, sand or rock dust Crushers may be used to reduce the size, or change the form, of waste materials so they can be more easily disposed of or recycled, or to reduce the size of a solid mix of raw materials (as in rock ore ), so that pieces of different composition

Primary and Secondary Crushing: Understanding the

Secondary crushing is the second stage of crushing that takes place after the primary crushing The secondary crusher is the equipment that reduces the size of the materials further, after they have

Primary Crusher vs Secondary Crusher:

The primary crusher is responsible for breaking down larger rocks and stones into manageable sizes, while the secondary crusher further refines these particles into the desired product While

primary amp secondary crushers digunakan dalam belt conveyor

Contribute to luoruoping/id development by creating an account on

Sand Belt Conveyor & Sand Conveyor Belt SKE Industries

There are many kinds of sand production line equipment including primary crusher, secondary crusher, fine crusher, vibrating screens, vibrating feeders, sand washing machines, sand conveyor machines Sand conveyor belt system in sand plant! A sand belt conveyor system may include sand producing and stockpiling During sand making

primary amp amp secondary crushers digunakan dalam belt conveyor

Contribute to luoruoping/id development by creating an account on

Efficient conveyor belt technology in large copper mine AMSJ

The Chuquicamata mine, situated in Chile’s north, has been in operation since 1915 and is owned by Codelco, Chile’s stateowned copper mining company Codelco is the world’s largest producer of copper and second largest producer of molybdenum Over 100 years of openpit mining have resulted in a mine that is some 1,000m deep, 5,000m

Selecting the right crusher Pit & Quarry

When selecting the crusher to best suit your operation, it’s important to understand your needs for each stage During the primary stage, look to get material to a size your conveyors and other processing machines can handle Some operations need further crushing in the secondary and tertiary crushing stages

Understanding the Crushing Stages of a Crusher

The primary task of the coarse crusher is to make it possible to transport the material on a conveyor belt it is often advantageous to use a portable primary crusher so that it can follow the movement of the work face from which the raw material is extracted Rotor Centrifugal Crusher Intermediate (secondary)

RATIONAL DESIGN OF CONVEYOR CHUTES TotalWEB! Lite

primary crusher, secondary crusher, and conveyor head chutes The bottoms of these dead boxes were lowered by 200 mm and to date no further blockages have occurred" "Blockages occurred at numerous conveyor transfer chutes Alterations included cutting away chute sides and providing chute covers A feed chute was widened from 100 mm to